[ad_1]

The Hummer EV Edition 1 will be the first vehicle that General Motors mass-produce using the Ultium battery architecture, introduced in March of this year, and Ultium Drive electric drives. These of the components These are the fundamental elements for this historic vehicle, in this electric version, to offer even better off-road performance than it did on combustion.

The electric Hummer will debut with General Motors-developed Ultium Drive technology based on a 800 volt electrical system which reduces the weight of the wiring and allows fast charging at 350 kW of power. It consists of state-of-the-art batteries, motors and transmissions that will be shared by all of its future electric models. The four variants with versions with two and three electric motors will reach ranges between 400 and 560 kilometers.

In autumn the Hummer EV Edition 1, with three electric motors, a total power of 1,000 hp and a range of 560 km. In autumn 2022 the Hummer EV3x with three engines, 482 km of autonomy and 811 hp. In the spring of 2023 the turn will be for Hummer EV2x with two engines, 482 km of autonomy and 634 hp. Finally, in the spring of 2024 the “simpler version” will arrive, the Hummer EV2, also with two engines, 400 km of autonomy and 634 HP.

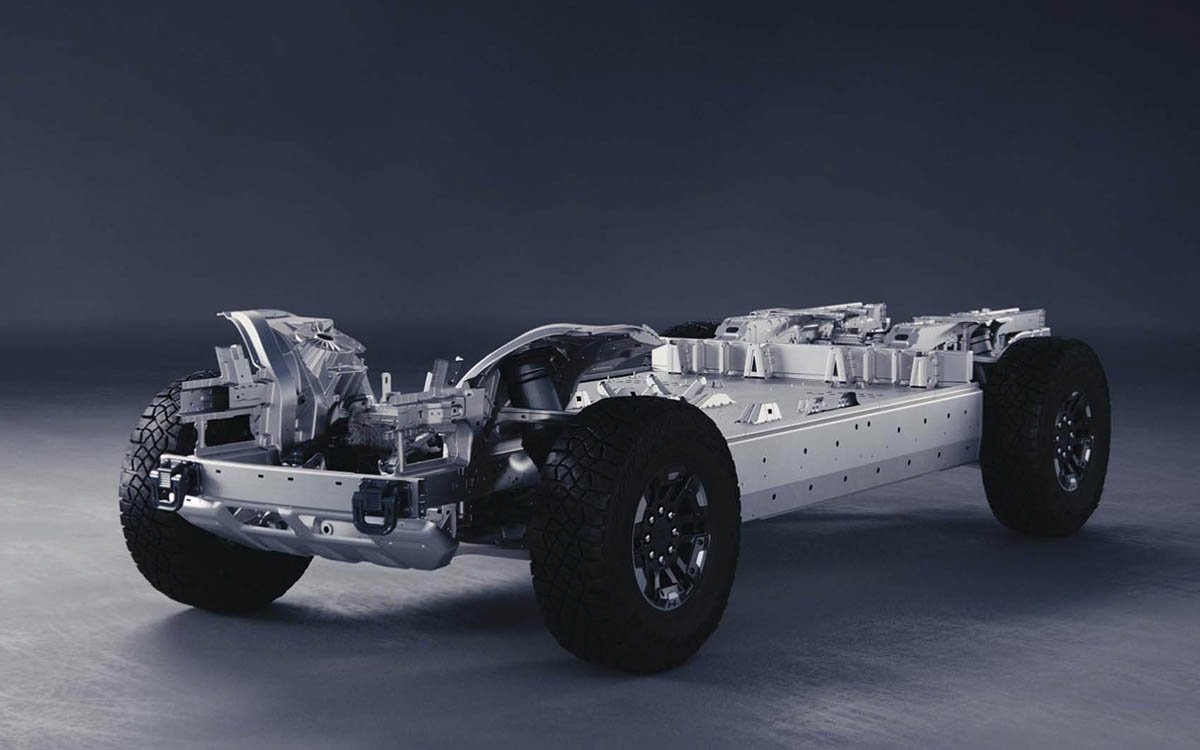

The battery: power, autonomy, fast charging and structural rigidity

The Hummer Edition 1 version battery integrated into the Ultium three-motor engine architecture provides the necessary structure to achieve this and the capabilities It wouldn’t be possible implement with a conventional vehicle architecture and powertrain. Is composed by bag cells large format that can be stacked vertically or horizontally inside the battery pack. In edition 1, the modules are mounted in two layers of vertical cells to generate the combined package which offers an estimated range of 560 kilometers.

The chemistry of its state-of-the-art electrodes is composed of nickel, cobalt, manganese and aluminum (NCMA). According to General Motors, they will have one of the highest nickel contents compared to large format bag cells on the market. In addition, they use 70% less cobalt than the Group’s previous generation of electric vehicles.

Above, the Hummer EV in its structural cabin. Below, the packaged battery and the cells and modules that compose it.

The Hummer EV has a 800 volt electrical system giving you the ability to take advantage of the DC fast chargers from 350 kW of power. A peculiarity of its battery is the possibility of changing the working voltage from 400 V native to the 800 volts it uses for recharging. A disconnect unit and a mechanical system allow parallel to series battery switch, adding nearly 160 kilometers of range in 10 minutes of charging.

The Ultium battery system will control the electric currents in the charging station through intelligent algorithms that reduce the intensity when needed and increase the charge rate. The charging system is also designed to support a 400 volt charging infrastructure, without the need for a converter box and other accessories, allowing compatible with a wide variety of charging stations.

The charging hardware will be completed by the myGMC smartphone app available via the central dash display, which will help customers find available charging locations and even pre-condition the battery for maximum efficiency for the next charging session.

Energy Assist, which is part of the myGMC app, will monitor the vehicle’s energy consumption. You will establish a charging schedule by preheating the battery when heading to a charging station and learn from the driver’s needs to display messages aimed at driving more efficiently and maximizing range. It will be accessible through the information and entertainment system, through a simple and intuitive interface, with easy to understand icons.

Additionally, the Hummer EV will also debut with General Motors’ wireless battery management system. The BMS (Battery Management System, for its acronym in English) is an electronic system that manages the charging and discharging of a battery. Among other things, it has the task of preventing it from operating outside its safe operating area by collecting data on its status, checking the individual voltage of each cell and balancing it when necessary. WBMS technology reduces the length of cables running inside an Ultium battery by 90%. The result is a very significant weight reduction that you can get used to increase your energy density and therefore its ability to deliver greater autonomy to electric cars to implement them.

In addition to allowing 1,000 hp of power and estimated range, the battery will help offer structural strength and increase driving dynamics. Its position, in the lower part of the frame, reduces the height of the center of gravity, improving the overall feeling of control and stability of the vehicle. The compact construction of the Ultium battery pack also helps generate the ideal proportions for 4×4 driving, with very short front and rear overhangs and an angle of attack and departure (up to 49.7º and 38.4º, respectively, with the suspension. pneumatic) too high.

Hummer EV battery, thrusters and transmissions.

Electric motors, up to 15,600 Nm of torque at the wheels

The three electric powertrains of Edition 1 will generate combined power, estimated by General Motors, from 1,000 hp, which when multiplied by the ratios between front and rear drive units, will lead to the wheels one per engine of 15,600 Nm.

The front drive unit, composed of a single engine, has a fixed gear ratio of 13.3: 1 and will offer an electronically locked differential, capable of delivering up to one hundred percent torque to a single wheel in the event of loss of traction on the opposite wheel on the same axis. All four wheels can be fully synchronized to provide true e4WD propulsion.

The two rear motors are contained in an Ultium Drive and independently drive the rear wheels through a fixed transmission ratio of 10.5: 1, with the possibility of varying the torque delivered to each wheel and optimizing traction in off-road or highway driving conditions. Furthermore, it is possible to synchronize the torque output to simulate a locking differential via the electronics.

The pure electric propulsion of the system allows you to maintain maximum torque for much longer, over a wider speed range (up to 65 km / h) than a diesel engine, a feature that optimizes both off-road capabilities and dynamic sensations on the road. Ultium batteries and Ultium Drive thrusters provide enough power to accelerate the Hummer EV from 0 to 100km / h in approximately three seconds, once mode is enabled Watts to freedom.

Electronic assistance systems for the field and on the road

He system Regenerates on request Offers a driver-controlled regenerative braking function, which converts the vehicle’s kinetic energy into electricity to be stored in the battery during deceleration and braking.

Hummer EV cockpit.

A lever on the steering wheel allows the driver to slow the vehicle to a complete stop without pressing the brake pedal. If the driver anticipates the need to slow down, the Hummer EV activates Regenerates on request before lifting the accelerator pedal, for more control over the operation. Unlike other regenerative braking systems, this allows the driver to decide when and to what extent to use the system.

The throttle adjustment It can be modified to suit the terrain, providing low-speed control that allows you to drive over difficult terrain regardless of obstacles in front of the vehicle.

The Hummer EV will debut with the latest version of the Super Cruise Driver Assistance System, which includes a new automatic lane change function. The system can determine when it is time to perform the maneuver based on traffic and signaling. Super Cruise uses a driver assistance system and map data generated by the included LiDAR sensor.

.

[ad_2]

Source link