[ad_1]

Japanese scientists have proposed a way to ensure longer catalyst life and higher growth rate by creating a CNT forest that is a record seven times longer than any existing CNT array. Credit: Waseda University

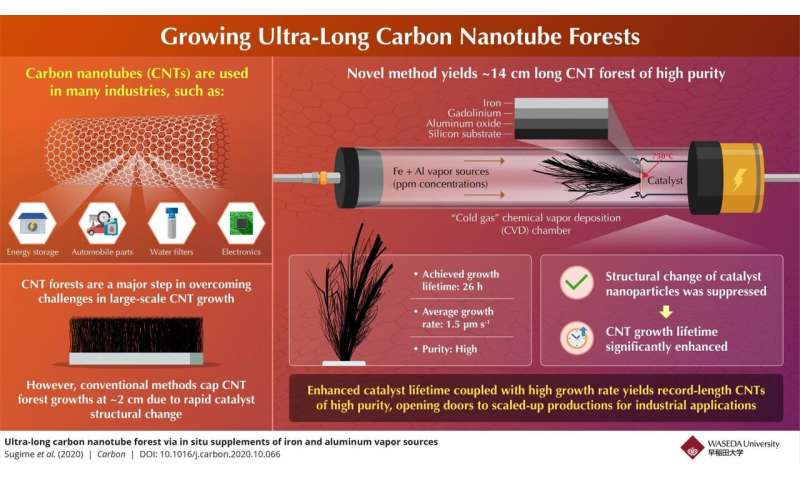

Today, a multitude of industries, including optics, electronics, water purification and drug delivery, innovate on an unprecedented scale with nano-sized honeycomb-shaped rolls of graphite called carbon nanotubes (CNTs). Features such as light weight, convenient construction, immense mechanical strength, superior thermal and electrical conductivities, and stability put CNTs a notch above other material alternatives. However, to meet their growing industrial demand, their production must be constantly increased, and herein lies the main challenge for the use of CNTs.

Although the scientists were able to grow single CNTs around 50cm in length, when they attempt to create arrays or forests, they reach a ceiling of around 2cm. This is because the catalyst, which is key to the growth of CNTs, is deactivated and / or depleted before the CNTs in a forest can grow further, increasing the monetary and raw material costs of CNT production and threatening to limit its industrial use.

Now, a ceiling breaking strategy has been devised by a team of Japanese scientists. In their study published in Carbon, the team presents a new approach to a conventional technique that produces CNT forests of record length: ~ 14 cm, seven times the previous maximum. Hisashi Sugime, assistant professor at Waseda University who led the team, explains: “In the conventional technique, CNTs stop growing due to a gradual structural change in the catalyst, so we focused on developing a new technique that suppresses this structural change and allows the CNT to grow for a longer period “.

The team created a catalyst based on the results of a previous study to begin with. They added a layer of gadolinium (Gd) to the conventional iron-aluminum oxide (Fe / Al2ORX) catalyst coated on a silicon (Si) substrate. This layer of Gd prevented the catalyst from deteriorating to some extent, allowing the forest to grow to about 5cm in length.

To further prevent deterioration of the catalyst, the team placed the catalyst in their original chamber called the cold gas chemical vapor deposition (CVD) chamber. There, they heated it to 750 ° C and provided it with small concentrations (parts per million) of Fe and Al vapors at room temperature.

This kept the catalyst strong for 26 hours, during which time a dense CNT forest could grow up to 14cm. Various analyzes to characterize the cultivated CNTs demonstrated that they were of high purity and competitive strength.

This result not only overcomes the obstacles to the widespread industrial application of CNTs, but opens the door to nanoscience research. “This simple yet innovative method that dramatically extends the life of the catalyst by providing vapor sources at the ppm level is intuitive for catalyst engineering in other fields such as petrochemistry and nanomaterial growth,” says Sugime. “The knowledge contained here could be key to making nanomaterials an omnipresent reality.”

How to roll a nanotube: Demystifying the control of the carbon nanotube structure

Hisashi Sugime et al, Ultra-long carbon nanotube forest via in situ integrators of iron and aluminum vapor sources, Carbon (2020). DOI: 10.1016 / j.carbon.2020.10.066

Provided by Waseda University

Quote: Scientists cultivate carbon nanotube forests much longer than any other (2020, November 4) recovered November 5, 2020 from https://phys.org/news/2020-11-scientists-carbon-nanotube-forest- longer.html

This document is subject to copyright. Apart from any conduct that is correct for private study or research purposes, no part may be reproduced without written permission. The content is provided for informational purposes only.

[ad_2]

Source link