[ad_1]

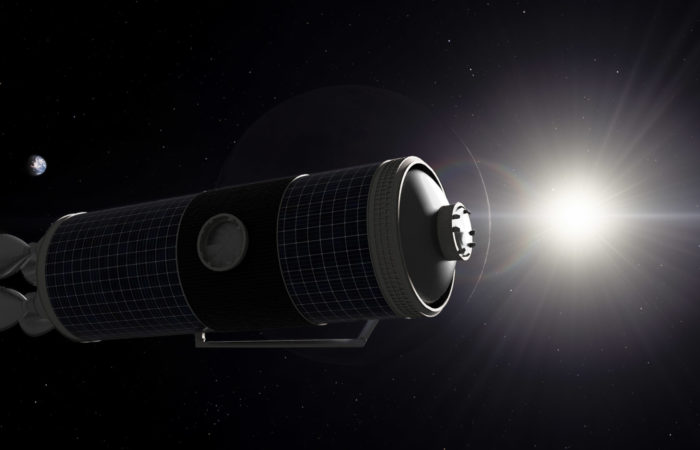

Since the 1950s, thousands of satellites have been launched into low Earth orbit. Now, one of the biggest problems in managing space traffic is how to dispose of thousands of inactive satellites and space equipment floating around like space junk.

Several ways that space junk has been cleaned up are through giant nets or magnets. Another solution to avoid the buildup of space pollution is to deorbit the rockets as soon as their payloads have been delivered. A third solution has also been proposed: recycling the metal parts to build space stations.

Reuse of spent rockets

Jeffrey Manber of Nanoracks, a logistics company that has provided several private space services for the International Space Station (ISS), has revealed plans to turn old rockets into mini space stations. While the idea isn’t new, it appears to be the right time to do so, especially as the ISS is expected to retire soon.

NASA has already looked into refurbishing fuel tanks in the past, Manber shared. However, the ideas were abandoned due to a lack of technology.

NASA’s ideas involved astronauts doing assembly and manufacturing work in space, which was potentially dangerous, expensive and slow. Manber’s most recent ideas involve autonomous robots performing welding work on spent rockets until they become appropriate parts for a space station. Miniature space stations could become laboratories, warehouses or even fuel depots.

Read also: The International Space Station deals with broken toilets as the astronauts return home

Nanoracks Space Outpost Program

The Nanoracks Space Outpost program will be launched next year in June to complete the first demonstration of robots that cut material from orbiting tanks. Success will be determined by the robot’s ability to reuse the spent rocket without producing additional debris.

There are typically two phases of a rocket launch involving an engine and propellant tanks. During the second phase, the payload is brought to orbital speed before being released and the rocket falls back to Earth. However, if the upper stage does not deorbit from the second stage, it also falls into orbit and becomes space debris.

The same parts are ideal for a space station, shared Nanoracks. For example, rocket fuel is designed to withstand pressure from launch, which means it can also withstand the harsh conditions of space. The upper stages are also quite large. SpaceX’s Falcon-9 upper stage is 9x12x30 feet wide, the size of a spacious apartment.

Nate Bishop, the manager of the Outpost project, shared that the team is currently focusing on showing how to control the upper stage with accessories like power supplies and experiment payloads. Later, “a bunch of little robots” will add connectors and other parts to create a space station.

“When I look into the future 15 or 20 years, there will be scout missions looking for good things to save,” Manber said. Potential customers will be looking for parts to use for future assembly in space.

“Outposts are our pillars of space exploration that focus on the concepts we love here on Earth: reuse and recycling,” the company wrote. For now, Nanoracks will focus on the upper stages of the new rockets. Later, the interior of the rockets will be developed in pressurized laboratories.

Read also: Space junk can now be monitored, even during the day

Find out more news and information about space stations in the Science Times.

.

[ad_2]

Source link