[ad_1]

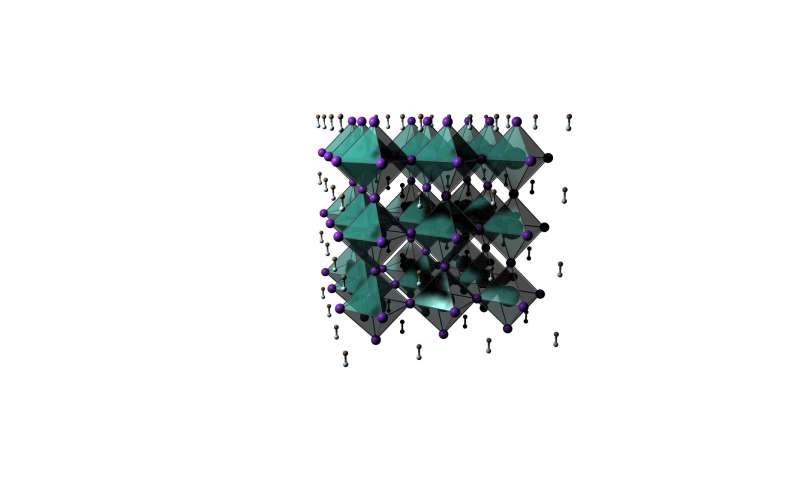

Perovskite structure. Credit: OSU College of Engineering

Electronic shirts that keep the wearer comfortably warm or cool, as well as medical fabrics that administer drugs, monitor the condition of a wound, and perform other tasks, may someday be manufactured more efficiently thanks to key advancements in Oregon State University researchers.

The breakthrough concerns inkjet printing and materials with a crystalline structure discovered almost two centuries ago. The result is the ability to apply circuits, precisely and at low processing temperatures, directly to the fabric, a promising potential solution to the long-standing trade-off between performance and manufacturing costs.

“A lot of effort has been made to integrate sensors, displays, power sources and logic circuits into various fabrics to create wearable electronic fabrics,” said Chih-Hung Chang, professor of chemical engineering at Oregon State. “One obstacle is that fabricating rigid devices on a fabric, which has a porous and uneven surface, is tedious and expensive, requires a lot of heat and energy, and is difficult to climb. And first put the devices on something solid, and then putting that solid substrate on the fabric is also problematic: it limits the flexibility and fit of the fabric and can even require cumbersome modifications to the fabric manufacturing process. “

Chang and collaborators at OSU College of Engineering and Rutgers University addressed these challenges by presenting a stable, printable ink, based on binary metal iodide salts, which thermally transforms into a dense compound of cesium, tin and iodine.

The resulting Cs2SnI6 film has a crystalline structure which makes it a perovskite.

The Perovskites trace their roots to a discovery long ago by a German mineralogist. In the Urals in 1839, Gustav Rose found a calcium titanium oxide with an intriguing crystalline structure and named it in honor of the Russian nobleman Lev Perovski.

Perovskite now refers to a range of materials that share the crystal lattice of the original. Interest in them began to accelerate in 2009 after a Japanese scientist, Tsutomu Miyasaka, discovered that some perovskites absorb light effectively. Materials with a perovskite structure based on a metal and a halogen such as iodine are semiconductors, essential components of most electrical circuits.

Thanks to the perovskite film, Chang’s team was able to print negative temperature coefficient thermistors directly onto polyester fabric at temperatures as high as 120 degrees Celsius, just 20 degrees above the boiling point of water.

A thermistor is a type of electrical component known as a resistor, which controls the amount of current that enters a circuit. Thermistors are resistors whose resistance depends on temperature and this research involved thermistors with negative temperature coefficient, or NTC, whose resistance decreases with increasing temperature.

“A change in resistance due to heat is generally not a good thing in a standard resistor, but the effect can be useful in many temperature sensing circuits,” Chang said. “NTC thermistors can be used in virtually any type of equipment where temperature plays a role. Even small changes in temperature can cause large changes in their resistance, making them ideal for accurate temperature measurements and controls.”

The research, which included Shujie Li and Alex Kosek of OSU College of Engineering and Mohammad Naim Jahangir and Rajiv Malhotra of Rutgers University, demonstrates the direct fabrication of high-performance NTC thermistors on fabrics at half the temperature used by the current state-of -the- art producers, Chang said.

“In addition to requiring more energy, the higher temperatures create compatibility problems with many fabrics,” he said. “The simplicity of our ink, process scalability, and thermistor performance all hold promise for the future of wearable e-textiles.”

The results were published in Advanced functional materials.

Researchers study the properties of more durable and efficient solar cell materials

Shujie Li et al, Perovskite inkjet printing for performance versus temperature trade-offs in fabric-based thermistors, Advanced functional materials (2020). DOI: 10.1002 / adfm.202006273

Provided by Oregon State University

Quote: Researchers Make Key Advances in Printing Circuits on Wearable Textiles (2020, November 12) Retrieved November 12, 2020 from https://phys.org/news/2020-11-key-advance-circuitry-wearable-fabrics. html

This document is subject to copyright. Apart from any conduct that is correct for private study or research purposes, no part may be reproduced without written permission. The content is provided for informational purposes only.

[ad_2]

Source link