[ad_1]

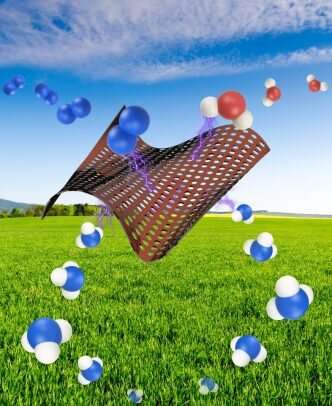

The electrochemical reduction of N.2 to NH3 offers a means of storing solar energy and distributed fertilizer production. The image shows the continuous capture of N2 from air and its conversion into NH3 high selectivity using electrocatalytic screens. Credit: Aditya Prajapati and Meenesh Singh

Ammonia is the second most commonly produced chemical in the world and an important component of most fertilizers, but current industrial processes to produce ammonia produce several million tons of carbon dioxide, a powerful greenhouse gas, every year.

Now, researchers led by Meenesh Singh, assistant professor of chemical engineering at the University of Illinois Chicago College of Engineering, describe a new process for producing ammonia with a potentially much lower carbon footprint. They report their findings in the journal DHW catalysis.

Nitrogen gas is one of the components used to make ammonia, but because the nitrogen bonds in nitrogen gas are very stable, a lot of energy is required to break them down so that the nitrogen can bond with hydrogen to produce ammonia.

“Current methods of producing ammonia from nitrogen are very energy-intensive and require burning fossil fuels to generate huge amounts of heat, and that produces a lot of greenhouse gases as a by-product,” Singh said.

Singh and colleagues have developed a new method of producing ammonia that relies on the use of a copper-coated mesh screen, a catalyst that helps bind nitrogen to hydrogen to produce ammonia. The electrification of the screen helps guide reactions.

Pure nitrogen gas is pushed through the screen and then interacts with water, which provides hydrogen. Although the Singh process uses similar amounts of energy to the traditional process, it requires far fewer fossil fuels than traditional methods, just enough to electrify the screen. “Electricity can come from solar or wind power, which would really make a huge difference in reducing greenhouse gas emissions,” Singh said. “Modern power generation plants are also highly efficient, and if the grid is conventionally powered, our process uses even fewer fossil fuels and generates fewer harmful greenhouse gases than conventional ammonia production.”

Currently, the Singh process produces 20% ammonia and 80% hydrogen gas. “We hope to increase ammonia production, but our early efforts so far are promising and the savings in carbon emissions are still significant if we were to scale up our process to produce large quantities of ammonia,” Singh said.

A provisional patent for the new process has been filed by the UIC Office of Technology Management.

Singh’s group is now looking to use air, instead of purified nitrogen gas, as a nitrogen source for ammonia production using their unique method. “Using air would allow us to save even more when it comes to greenhouse gases, because we use readily available air instead of nitrogen gas, which has to be purified and bottled.”

The new technique seamlessly converts ammonia into green hydrogen

Nishithan C. Kani et al, Competing Effects of pH, Cation Identity, H.2O Saturation and N2 Concentration on the activity and selectivity of the electrochemical reduction of N.2 to NH3 on electrodeposited Cu in environmental conditions, DHW catalysis (2020). DOI: 10.1021 / acscatal.0c04864

Provided by the University of Illinois at Chicago

Quote: Researchers identify new process for producing ammonia with a much smaller carbon footprint (2020, Dec 1) recovered Dec 1, 2020 from https://phys.org/news/2020-12-ammonia-smaller- carbon-footprint.html

This document is subject to copyright. Aside from any conduct that is correct for private study or research purposes, no part may be reproduced without written permission. The content is provided for informational purposes only.

[ad_2]

Source link