[ad_1]

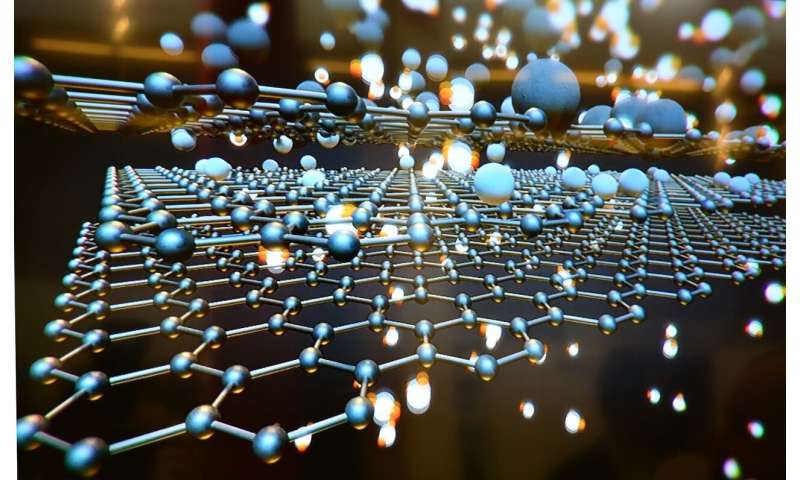

Credit: Public Domain CC0

A new way to deposit thin layers of atoms as a coating on a substrate material at room temperature was invented at the University of Alabama in Huntsville (UAH), a part of the University of Alabama System.

UAH postdoctoral research associate Dr. Moonhyung Jang came up with the idea of using ultrasonic atomization technology to evaporate chemicals used in atomic layer deposition (ALD) while purchasing a home humidifier .

Dr. Jang works in the laboratory of Dr. Yu Lei, an associate professor in the chemical engineering department. The two published an article on their invention which was selected as a publisher’s choice in Journal of Vacuum Science & Technology A.

“ALD is a three-dimensional thin-film deposition technique that plays an important role in microelectronics manufacturing, in the production of items such as central processing units, memory and hard drives,” says Dr. She.

Each ALD cycle deposits a few atoms deep layer. An ALD process repeats the deposition cycle hundreds or thousands of times. The uniformity of thin films is based on a self-limiting surface reaction between the vapor of the chemical precursor and the substrates.

“ALD offers exceptional control of nano characteristics while depositing materials evenly on large silicon wafers for high-volume manufacturing,” says Dr. Lei. “It’s a key technique for producing small and powerful smart devices.”

While browsing online for a safe and easy-to-use home humidifier, Dr. Jang noted that the humidifiers on the market use direct high-temperature heating or vibrating ambient-temperature ultrasonic atomizer to generate the water mist.

“Moon suddenly realized that the latter could be a simple and safe way to generate vapors for reactive chemicals that are thermally unstable,” says Dr. She.

“The next day, Moon came to discuss the idea and we designed the experiments to prove the concept in our research lab. The whole process took almost a year. But the big idea came to Moon like a flash.” .

ALD processes typically rely on heated gas phase molecules that are evaporated from their solid or liquid form, similar to room humidifiers that use heat to vaporize water. However, in that ALD process, some chemical precursors are not stable and can decompose before reaching sufficient vapor pressure for ALD.

“In the past, many reactive chemicals were considered unsuitable for ALD due to their low vapor pressure and because they are thermally unstable,” says Dr. Her. “Our research found that the ultrasonic atomizer technique allowed reactive chemicals to evaporate at a minimum room temperature.”

The invention of ultrasound by UAH scientists makes it possible to use a wide range of reactive chemicals that are thermally unstable and unsuitable for direct heating.

“Ultrasonic atomization, as developed by our research group, provides low vapor pressure precursors because the evaporation of the precursors was done via the ultrasonic vibration of the module,” says Dr. She.

“Like the home humidifier, ultrasonic atomization generates a mist made up of saturated vapor and micro-sized droplets,” he says. “The micro-sized droplets evaporate continuously when the mist is delivered to the substrates by a carrier gas.”

The process uses a piezoelectric ultrasonic transducer placed in a liquid chemical precursor. Once started, the transducer starts vibrating a few hundred thousand times per second and generates a fog of the chemical precursor. The small liquid droplets in the mist are quickly evaporated in the gas collector under vacuum and with a light heat treatment, leaving behind a uniform layer of the deposition material.

“Using the room temperature ultrasonic atomization reported by our manuscript, novel ALD processes could be developed using low volatility and unstable precursors,” says Dr. Her. “A new window will open for many ALD processes.”

In their paper, UAH researchers demonstrate proof of concept by comparing titanium oxide ALD using thermally evaporated and room temperature atomized chemical precursors, respectively.

“The TiO2 the quality of the thin film is comparable, “says Dr. Lei.

New chemistry for ultra-thin gas sensors

Henrik H. Sønsteby et al. tert-butoxides as precursors for the deposition of atomic layers of thin films containing alkali metals, Journal of Vacuum Science & Technology A (2020). DOI: 10.1116 / 6.0000589

Provided by the University of Alabama at Huntsville

Quote: Researchers develop new atomic layer deposition process (2020, October 27) recovered on October 27, 2020 from https://phys.org/news/2020-10-atomic-layer-deposition.html

This document is subject to copyright. Aside from any conduct that is correct for private study or research purposes, no part may be reproduced without written permission. The content is provided for informational purposes only.

[ad_2]

Source link