[ad_1]

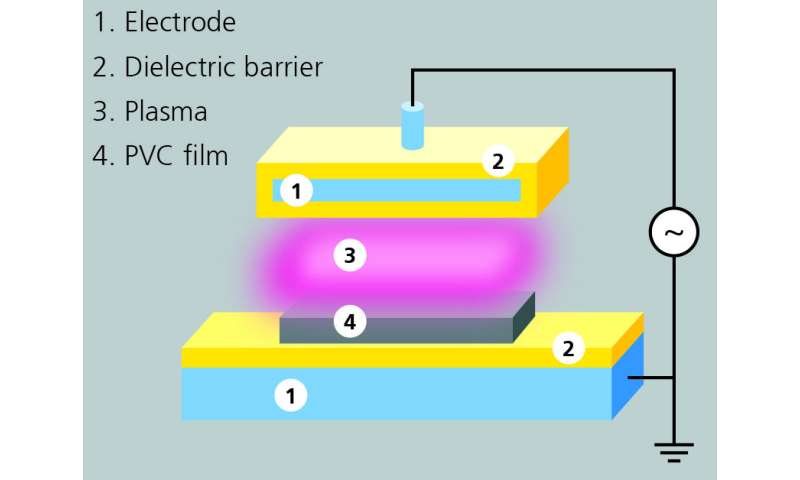

Experimental assembly for the DBD treatment (dielectric barrier discharge) of PVC film. Credit: Fraunhofer IST

Medical products such as blood bags and tubes are often made of soft PVC, a plastic that contains phthalate plasticizers, which are suspected to be harmful to human health. These substances are not chemically bound to the polymer, which means they can seep into blood bags and thus come into contact with human cells. A new method developed at the Fraunhofer Institute for Surface Engineering and Thin Films IST prevents these harmful substances from migrating into the surrounding medium.

Plasticizers are found in many everyday items, but also in medical products. They are added to polymers to give materials greater elasticity and flexibility. Blood bags and medical tubes often contain DEHP (diethylhexyl phthalate), a PVC additive that can adversely affect human health. The EU has classified DEHP, a member of the phthalates class of substances, as toxic for reproduction. Manufacturers must therefore obtain approval to use this plasticizer in the EU and its use in cosmetics and toys is prohibited. However, it is still found in soft PVC, which is used to make blood bags. “Soft PVC contains up to 40% by weight of DEHP plasticizers. Since the plasticizer molecules are not chemically bound to PVC, they can migrate into the environment,” says Dr. Thomas Neubert, physicist at the Fraunhofer IST in Braunschweig. He and his colleagues use atmospheric pressure plasma processes to change the molecular structure of the plasticizer on the plastic surface and to crosslink the molecules in such a way as to prevent the harmful substance from passing through the crosslinked lattice. “We produce reactive species and high-energy UV radiation in the plasma. These penetrate the surface of the PVC and break the chemical bonds in the plasticizer molecules, which then bond with adjacent molecules. The resulting mesh forms a protective barrier that DEHP cannot penetrate. “, explains Neubert. The PVC itself is not modified: its mechanical properties are preserved.

95% barrier effect

Tests by researchers showed that plasticizer migration from soft PVC could be reduced by 95%. To determine the barrier effect, the treated PVC films are stored in n-decane, a solvent, for two hours to identify the amount of migrated plasticizers. To test the long-term stability of the barriers, the treated soft PVC films were stored in the air for four months. They found that the molecular lattice produced does not dissolve and the 95% barrier effect is preserved. The tests were conducted with PVC films used for the production of blood bags. These results can also be extrapolated to other phthalate plasticizers, such as TOTM (tri- (2-ethylhexyl) trimellitate) or DINP (diisononyl phthalate).

Aldyne system for continuous roll-to-roll functionalization, crosslinking and coating. Credit: Fraunhofer IST / Falko Oldenburg

Plasma treatment at atmospheric pressure

But how does this process work in detail? To prevent the migration of plasticizers, Neubert and his team use dielectric barrier discharges at atmospheric pressure. This involves placing the PVC film between two metal electrodes with a dielectric barrier. The researchers apply a high alternating voltage of several thousand volts to each electrode, over which a dielectric barrier gas discharge occurs in the gas gap between the electrodes. “In the resulting plasma, we produce short-wave UV radiation that breaks up the plasticizer molecules. The fragments of the molecule want to react with each other and form a network,” Neubert says. Pure argon is used as a process gas, which is easy to ionize and relatively inexpensive.

For Neubert, atmospheric pressure plasma treatment is the tool of choice, as it is significantly cheaper than coating processes, which may also prevent plasticizer migration. “Coating processes have to meet high requirements. Coatings need to fit optimally and be flexible. Plus, they have to go through an elaborate approval process for medical products.” The researcher and his team are currently working to make their process suitable for industrial use and to speed it up sufficiently to allow the processing of several meters of PVC film per second in roll-to-roll processing.

Nail polishes with “n-free” labels are not necessarily free of toxic compounds

Provided by Fraunhofer Society

Quote: Plasma treatment reduces migration of plasticizers from blood bags (2020, December 1) recovered December 1, 2020 from https://phys.org/news/2020-12-plasma-treatment-migration-plasticizers-blood .html

This document is subject to copyright. Aside from any conduct that is correct for private study or research purposes, no part may be reproduced without written permission. The content is provided for informational purposes only.

[ad_2]

Source link