[ad_1]

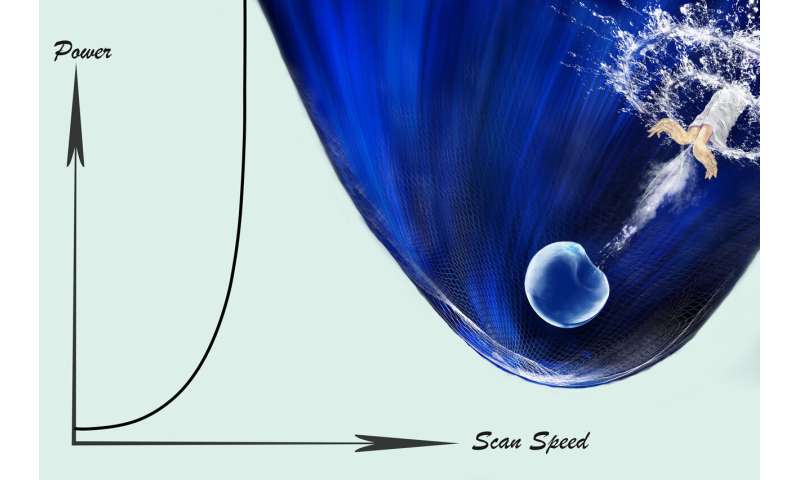

Artwork showing the boundary and origin of the keyhole porosity. On the left side of the figure, the boundary of the porosity of the keyhole in the space laser power – scanning speed is sharp and uniform. On the right side, around the porosity limit, the critical instability of the keyhole releases acoustic waves (shock waves) into the melt pool. The waves then drive the pore near the tip of the keyhole to quickly accelerate away from the keyhole. When the pore is captured by the solidification front, it becomes a damaging structural defect in the construction. Credit: Ye Feng, Cang Zhao at Tsinghua University

Powder bed laser melting is a dominant additive manufacturing technology that has yet to reach its potential. The problem the industry faces is that sometimes tiny bubbles or pores form during the printing process and these pores create weak spots in the finished products.

When a low-speed, high-power laser melts metal powder during 3-D printing of a part, a keyhole-shaped cavity in the weld pool can result. Pores, i.e. defects, form at the bottom of the keyhole. New research published in Science reveals how pores are generated and become defects trapped in the solidifying metal.

“The real practical value of this research is that we can be precise about machine control to avoid this problem,” says Anthony D. Rollett, professor of materials science and engineering at Carnegie Mellon College of Engineering and lead co-author of the paper, ” Critical instability at the tip of the moving keyhole generates porosity in the laser melt. “

Building on previous research that quantified the keyhole phenomenon, the research team used extremely bright high-energy X-ray images to observe the keyhole instabilities. Pores form during keyhole fluctuations and change its shape: the keyhole tip turns into a “J” shape and pinches. This unstable behavior generates acoustic waves in the liquid metal that push the pores away from the keyhole so that they survive long enough to be trapped in the resolidifying metal. The team is the first to focus on this behavior and identify what’s going on.

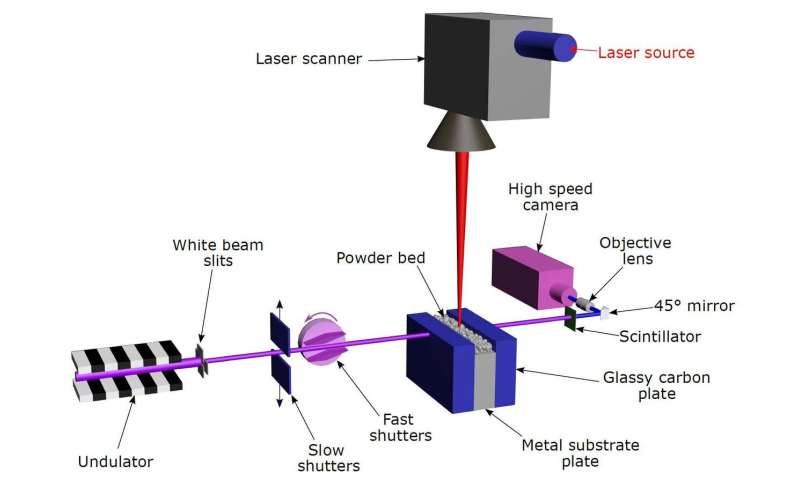

Scheme of the X-ray experiment operating synchrotron on laser powder bed fusion (LPBF), with X-ray optics to control the beam, sample holder with glassy carbon plates to contain dust, scintillator to convert X-rays into light, high-resolution camera speed to capture movies and high power laser with scan head to deliver a laser beam to melt the sample surface. Credit: Carnegie Mellon University College of Engineering

“When you have a deep keyhole, the walls wobble strongly. Occasionally, the wobbles are strong enough at the bottom of the keyhole to come loose, leaving a large bubble behind. Sometimes this bubble won’t reconnect. never at the main keyhole. It collapses and generates an acoustic shock wave. This moves the remaining pores away from the keyhole, “says Rollett.

It is important to note that the keyholes themselves are not defects and, for example, increase the efficiency of the laser. Using synchrotron X-ray equipment at Argonne National Laboratories, the only facility in the United States where the researchers could perform these experiments, they noticed that there is a well-defined boundary between stable and unstable keyholes.

“As long as you stay out of the danger zone [i.e., too hot, too slow], the risk of leaving defects is quite small, “says Rollett.

Fluctuations in the depth of the keyhole increase strongly with decreasing scanning speed and laser power on the unstable side of the border.

“You can think of the limit as a speed limit, except that it is the opposite of driving a car. In this case, it becomes more dangerous as you go slower. If you are below the speed limit , you are almost certainly generating a defect, “adds Rollett.

On a larger scale, by demonstrating the existence of well-defined keyhole porosity boundaries and demonstrating the ability to reproduce them, science can offer a more secure basis for predicting and improving printing processes. Rollett, who is the faculty co-director of Carnegie Mellon’s Next Manufacturing Center, thinks the results of this research will soon find their way into how companies manage their 3-D printers.

Finding keyholes in metal 3D printing

C. Zhao from Tsinghua University in Beijing, China and others, “Critical instability at the tip of the moving keyhole generates porosity in laser melting,” Science (2020). science.sciencemag.org/cgi/doi… 1126 / science.abd1587

Provided by Carnegie Mellon University

Quote: A Path to Avoiding Defects During Additive Manufacturing (2020, November 26) Retrieved November 26, 2020 from https://phys.org/news/2020-11-route-defects-additive.html

This document is subject to copyright. Aside from any conduct that is correct for private study or research purposes, no part may be reproduced without written permission. The content is provided for informational purposes only.

[ad_2]

Source link