[ad_1]

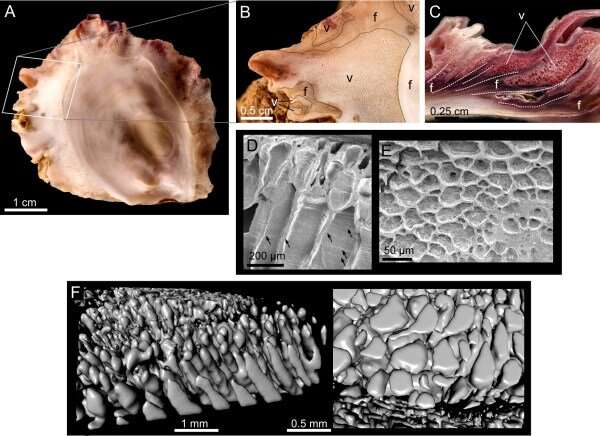

Vesicular microstructure of gryphaeid oysters. Credit: University of Granada

Scientists from the University of Granada (UGR) have found that oysters are capable of producing three-dimensional structures organized by physical (colloidal) processes – the result of which resembles a solid foam – using a unique technique, similar to that of a 3 – D printer. This technique allows them to develop their shell structures sheet by sheet, which solves the problem of limited extrapallial space (the small space that separates the mollusk from its shell). The results of this study were published in the prestigious Journal of the Royal Society Interface.

Oysters and, in general, mollusks (as well as other groups of invertebrates) form their shells in an extremely small space (much less than a micron) that lies between the living tissue that secretes the shell (mantle) and growth surface of the shell which exists in all molluscs. This is the so-called extrapallial space (pallium meaning mantle). It has the shape of a very thin film and is filled with an aqueous liquid called extrapallial fluid. It is therefore quite extraordinary that oysters can produce vesicles (hollow cavities) measuring tens – sometimes hundreds – of microns in diameter across this very small space.

The Gryphaeidae oyster family was an important group during the Jurassic period (between 201 and 145 million years ago), although very few remain today. Some groups of this family exclusively developed, around the Cretaceous period, a highly porous material called vesicular.

“This material consists of vesicles filled with an aqueous liquid, surrounded by calcite walls. Since it is not a very dense material, through the interleaving of vesicular lenses, the oyster develops a shell that is both strong and light. It means also that thick shells can be produced with a considerable saving of metabolically expensive building material “, explains Professor Antonio Checa, researcher at the Department of Stratigraphy and Paleontology of the UGR and principal author of this work.

The study conducted at the UGR focused on how these oysters build their vesicular layers. “In addition to other techniques, we relied on three-dimensional reconstructions and measurements of the vesicular layers of today’s gryphaeid oysters taken with a computed tomography scanner from the UGR’s Center for Scientific Instrumentation (CIC). All results show that the vesicular material has topological properties and behaviors similar to those of a solid foam “, explains Checa.

An emulsion within the extra-pallial space

The researchers concluded that the oyster produces this material by first creating an emulsion within the extrapallial space between the liquid precursor of the calcite walls and the extrapallial fluid. Importantly, foams (gas-liquid systems) and emulsions (liquid-liquid systems) are colloidal systems that obey the same laws and behave in a similar way. As growth occurs, the precursor liquid of calcite crystallizes, creating “bubbles” whose walls solidify. These are then incorporated into the vesicular layer, simultaneously with the movement of the extrapallial space and, within it, the emulsion continues to evolve.

“For this mechanism to work, each cell of the mantle must be able to recognize (through contact recognition) the component or components (liquid precursor for calcite or extrapallial fluid) of the emulsion with which it is in contact and to continue secreting one or more the other, according to this information, “says the UGR professor.

While the foaming process typically takes place in large spaces and bubbles are created and disappear all at once, foam oysters have developed their own “ technology ” that allows them to develop these sheets sheet by sheet, just like a 3-D printer. In this way, they solved the problem of space limitations of extra-pallet space. Thus, the vesicular material of oysters is under double control: physical (self-organization of an emulsion) and biological (sophisticated cellular behavior).

The mineralized materials secreted by organisms, of which there is a wide variety, pose very interesting biophysical problems. They are also of considerable interest in the field of materials science because they have exceptional biomechanical properties (lightness, strength and flexibility), in addition to those of their individual components (basically calcium carbonate and organic matter). Hence, they provide inspiration for the development of new highly functional synthetic compounds.

Image: The foam enlargement experiment on the ISS

Antonio G. Checa et al. Foamy oysters: production of vesicular microstructure in Gryphaeidae by emulsification, Journal of The Royal Society Interface (2020). DOI: 10.1098 / rsif.2020.0505

Provided by the University of Granada

Quote: Oysters produce 3-D structures organized by physical processes (2020, November 18) recovered November 18, 2020 from https://phys.org/news/2020-11-oysters-d-organised-physical.html

This document is subject to copyright. Apart from any conduct that is correct for private study or research purposes, no part may be reproduced without written permission. The content is provided for informational purposes only.

[ad_2]

Source link