[ad_1]

(Nanowerk News) Forget glue, screws, heat, or other traditional bonding methods. A collaboration led by Cornell University has developed a 3D printing technique that creates cellular metallic materials by shattering dust particles together at supersonic speed.

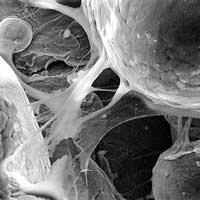

This form of technology, known as ?? cold spray, ?? results in mechanically robust porous structures that are 40% stronger than similar materials made with conventional manufacturing processes. The structures ?? their small size and porosity make them particularly suitable for the construction of biomedical components, such as spare joints.

The team article published in Materials applied today (“Solid-state additive manufacturing of porous Ti-6Al-4V by Supersonic Impact”).

The lead author of the article is Atieh Moridi, assistant professor at the Sibley School of Mechanical and Aerospace Engineering.

?? We have focused on building cell structures, which have many applications in thermal management, energy absorption and biomedicine, ?? Moridi said. Instead of just using heat as an input or driving force for bonding, we are now using plastic deformation to bind these dust particles together.

Moridi’s research group specializes in the creation of high-performance metallic materials through additive manufacturing processes. Rather than carving a geometric shape from a large block of material, additive manufacturing builds the product layer by layer, a bottom-up approach that gives manufacturers more flexibility in what they create.

However, additive manufacturing is not without its challenges. Chief among them: metallic materials must be heated to high temperatures that exceed their melting point, which can cause build-up of residual voltages, distortions and unwanted phase transformations.

To eliminate these problems, Moridi and collaborators have developed a method that uses a compressed gas nozzle to shoot titanium alloy particles onto a substrate.

?? It’s like painting, but things develop a lot more in 3D, ?? Moridi said.

The particles were between 45 and 106 microns in diameter (one micron is one millionth of a meter) and traveled at about 600 meters per second, faster than the speed of sound. To put this into perspective, another traditional additive process, direct energy deposition, delivers powders through a nozzle at a speed of the order of 10 meters per second, making Moridi’s method sixty times faster.

Particles aren’t just thrown out as fast as possible. The researchers had to carefully calibrate the ideal speed of the titanium alloy. Typically in cold spray printing, a particle would accelerate at the optimum point between its critical speed ?? the speed at which a dense solid can be formed ?? and its rate of erosion, when it crumbles too much to bind to anything.

Instead, Moridi’s team used computational fluid dynamics to determine a velocity just below the critical velocity of the titanium alloy particle. When launched at this slightly slower speed, the particles created a more porous structure, ideal for biomedical applications, such as artificial knee or hip joints and cranial / facial implants.

?? If we make implants with this type of porous structures and insert them into the body, the bone can grow inside these pores and create a biological fixation, ?? Moridi said. ?? This helps reduce the likelihood of implant loosening. And this is a big problem. There are many revision surgeries that patients need to have the implant removed just because it is loose and causes a lot of pain.

Although the process is technically referred to as cold spray, it involved heat treatment. Once the particles collided and bonded together, the researchers heated the metal so that the components diffused into each other and settled as a homogeneous material.

?? We have focused only on titanium alloys and biomedical applications, but the applicability of this process could go further, ?? Moridi said. Basically, any metal material that can withstand plastic deformation could benefit from this process. And it opens up many opportunities for large-scale industrial applications, such as construction, transportation and energy. ??

Source link